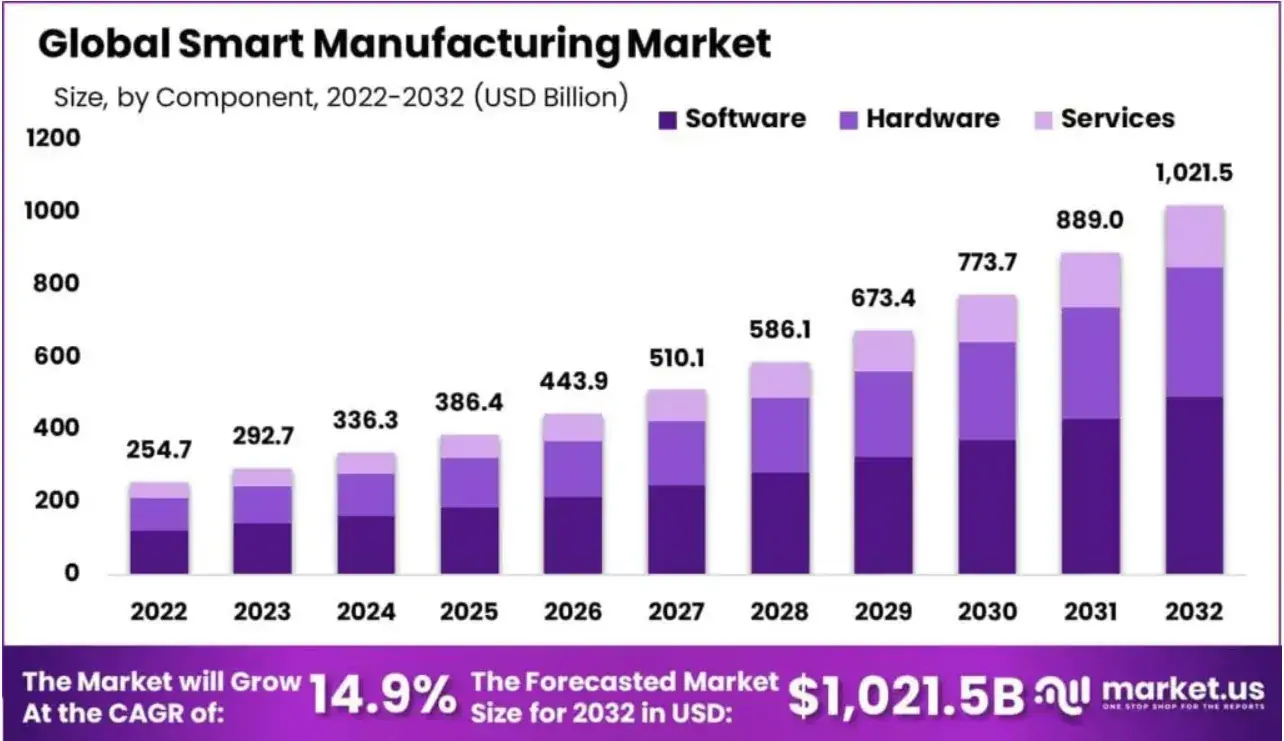

Unexpected machine downtime is costing leading global corporations (Fortune Global 500) an estimated USD 1.4 trillion per year, equivalent to around 11% of their annual revenue. To address this massive loss, factories worldwide are transitioning toward smart manufacturing, leveraging AI and IoT to analyze data, optimize efficiency, ensure quality control, and reduce operational costs. This is an inevitable trend, with the global smart manufacturing market projected to more than double by 2032.

From automation to intelligence

While the third industrial revolution ushered in automation, the Fourth Industrial Revolution (Industry 4.0) has redefined the landscape with breakthrough technologies such as Artificial Intelligence (AI), Internet of Things (IoT), Big Data, and Cloud Computing — forming the foundation of a truly intelligent world.

Through AI, operational data can be analyzed in real time to optimize workflows, forecast maintenance, and improve planning. IoT creates interconnected sensor networks spanning production lines and logistics, enabling remote monitoring and control. Big Data processes massive datasets across production, markets, and supply chains, while Cloud platforms provide flexible infrastructure for large-scale integration and coordination. The Smart Factory is the ultimate manifestation of this transformation — where machines, people, and data interconnect within a continuously self-optimizing ecosystem.

Smart factory: Data-driven operations

Recognizing this trend, a leading fertilizer and petrochemical manufacturer in Vietnam has launched the Smart Factory Upgrade Program, building a data backbone that connects all processes — from procurement and production to maintenance, quality, and logistics — through a centralized management platform and real-time dashboards for decision-making. The roadmap envisions a self-operating, data-driven factory that is safer, more energy-efficient, and environmentally sustainable.

The stages of smart factory development

Transitioning to a smart manufacturing system occurs through several maturity stages. According to international frameworks such as SIRI (EDB Singapore) and Industrie 4.0 Maturity Index (acatech), businesses must identify their current level and upgrade systematically:

- Level 1 – Analog Factory: Manual operations, no digitalization, data handled manually and scattered across systems.

- Level 2 – Digitized Factory: Partial digitalization through SCADA, ERP; localized data; automation in some processes. (Example: Dam Ca Mau Fertilizer Plant is currently at this stage and advancing to level 3.)

- Level 3 – Connected/Integrated Factory: Centralized data integration with IoT, MES, and basic AI for decision support.

- Level 4 – Autonomous Factory: Fully integrated system capable of self-analysis and decision-making; nearly all production, operation, and management activities are automated.

At each level, the benefits become increasingly evident — minimizing downtime, optimizing performance, improving quality, enabling predictive maintenance, managing supply chains efficiently, ensuring workplace safety, and reducing emissions while saving energy.

TMA Innovation: Partnering in the transformation journey

TMA Innovation delivers tailored smart manufacturing solutions built upon advanced technologies, enabling factories to progress step-by-step — from data collection and remote monitoring to AI-powered maintenance, safety, and sustainability. TMA’s solution ecosystem includes key capabilities:Remote monitoring and control, automation, machine optimization, AI in manufacturing, 3D simulation, product inspection, safety and security solutions, environmental and energy management, and machine data collection.

Phase 1: Digitalization & Connectivity

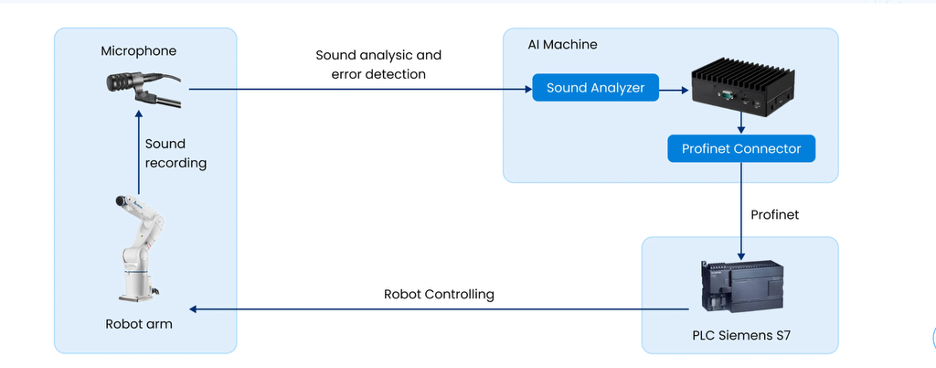

- Collecting machine data for real-time monitoring, performance analysis, predictive maintenance, and production management integration.

- Remote monitoring and control systems (Machine/Staff/Tool/Energy–Environment management) integrated with CMMS/EAM for maintenance operations.

Phase 2: Integration & Optimization

- Process automation with abnormality detection and real-time visualization.

- AI in manufacturing for early defect detection, automated quality inspection, and optimized scheduling/resources.

- Computer vision-based product inspection for items such as FPCBs and water valves.

- Machine optimization through predictive analytics, QR-based asset management, and automated scheduling.

Phase 3: Autonomy & Sustainability

- Environmental & energy (ESG) solutions: Smart energy management, automatic control systems, remote monitoring of devices (pumps, power meters), real-time sensors, operational logging, and intuitive visualization.

TMA is committed to providing comprehensive Smart Factory systems with remote management, high transparency, enhanced competitiveness, and improved product quality — key advantages detailed on the TMA Smart Manufacturing Solutions page.

Practical applications of TMA’s technologies

Facial recognition access control for SAMCO: Implemented across three offices, improving security, optimizing entry management, and reducing operational costs.

T-Locker smart storage at Emart Sala: Facial recognition lockers for safe, contactless delivery and pickup — reducing staffing needs and enhancing customer experience.

AI-based product inspection system: Detects over 50 types of FPCB/AOI defects and identifies water valve anomalies, showcasing TMA’s computer vision and automated inspection capabilities.

About TMA Innovation

A member of TMA Technology Group, TMA Innovation inherits over 28 years of experience delivering thousands of technology solutions for global corporations. Backed by a team of 4,000 engineers, TMA Innovation applies cutting-edge technologies to provide creative and breakthrough solutions across diverse industries.

The Smart Manufacturing Solution Center at TMA Innovation focuses on helping enterprises enhance production quality, strengthen competitiveness, reduce costs, and ensure safety and sustainability.