Functions

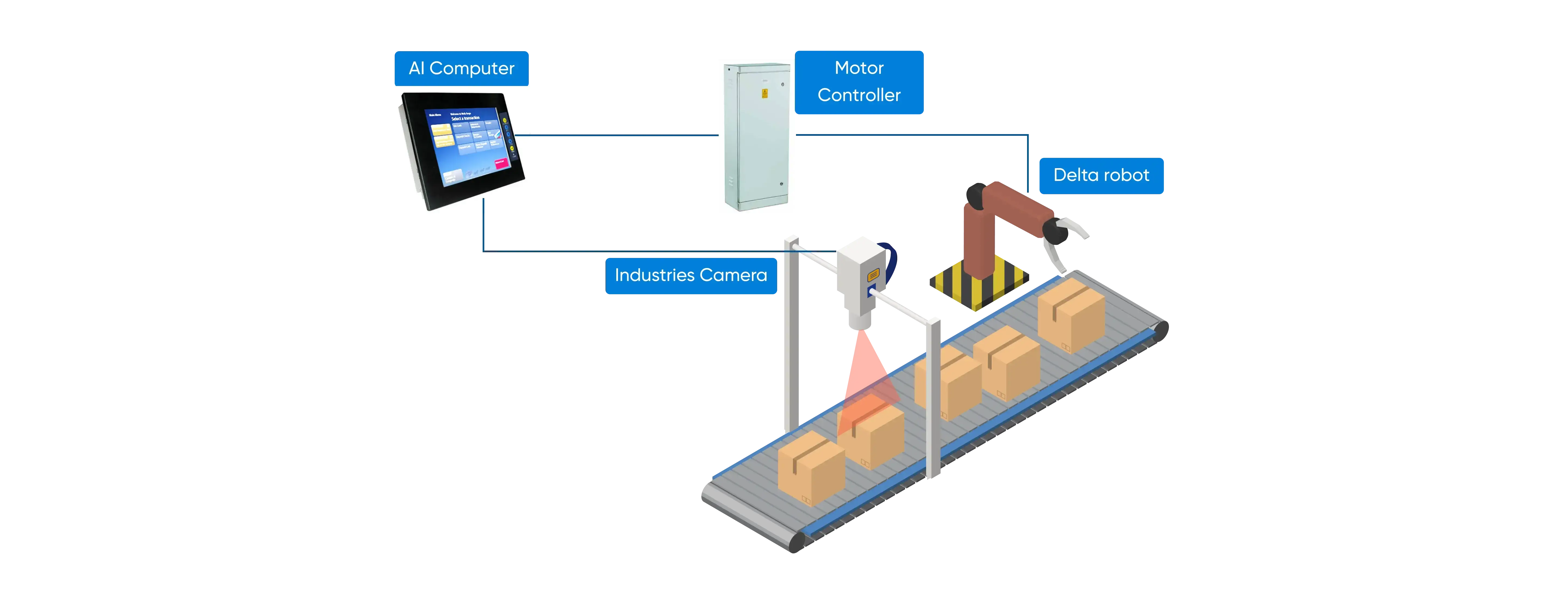

Detect and recognize products using AI-powered vision systems in real-time

Analyze product features (e.g., size, shape, color, defects) to assess quality

Automatically classify products into different categories (e.g., good vs. faulty)

Control robotic arms to sort or remove substandard items from the conveyor

Track and log inspection data for quality control and production analysis

Support customizable classification rules based on production needs

Benefits

Improves product quality control by detecting defects early and accurately

Increases production efficiency through automated classification and sorting

Reduces manual labor costs and minimizes human error in inspection tasks

Enhances consistency and reliability in product evaluation and sorting

Supports real-time monitoring and decision-making with data logging and analysis

Scales easily for different product types and classification rules